Stepping inside a working chocolate factory is very different from seeing finished chocolate on a shelf. The space is quiet, controlled, and deliberate. Temperature, humidity, and timing all matter. Every step in the process affects how the chocolate will taste, feel, and perform once it reaches the end user.

A true chocolate factory is less about volume and more about precision. Especially when the focus is on luxury handmade chocolate, where small variations in process can make a noticeable difference.

What Happens Inside a Chocolate Studio

The process begins long before moulds are filled. Ingredients are assessed, tempered, tested, and adjusted based on conditions in the room. Luxury chocolate, particularly couverture, is sensitive. It responds to temperature shifts, moisture in the air, and even how long it rests between stages.

Tempering is one of the most critical steps. Chocolate must be heated and cooled in a precise sequence to stabilise the cocoa butter crystals. This determines the final shine, snap, and melt of the chocolate. If this step is rushed or poorly controlled, the result is dull, soft, or unstable chocolate.

Once tempered, the chocolate is poured, filled, or shaped by hand. In a small-batch environment, this allows for careful inspection of each piece. Imperfections are corrected immediately rather than passing unnoticed down a production line.

After setting, chocolates rest in climate-controlled conditions. This stage is often overlooked, but it is essential. Proper resting allows the structure of the chocolate to stabilise before packaging, which directly impacts shelf life and texture.

Why Luxury Handmade Chocolate is Unique

Luxury handmade chocolate uses high cocoa content couverture, which contains a higher percentage of cocoa butter. This gives it a smoother mouthfeel and cleaner melt, but it also makes it more delicate.

Couverture chocolate has a shorter shelf life than mass-produced alternatives. In many cases, it is measured in weeks rather than months. It is also more sensitive to heat, light, and handling.

This is why luxury chocolate cannot be treated like standard confectionery. Storage conditions, transport methods, and turnover all matter. When these factors are ignored, quality declines quickly.

Factories producing handcrafted chocolate in Cape Town are built around managing these sensitivities rather than working against them.

Packaging and Handling Inside the Studio

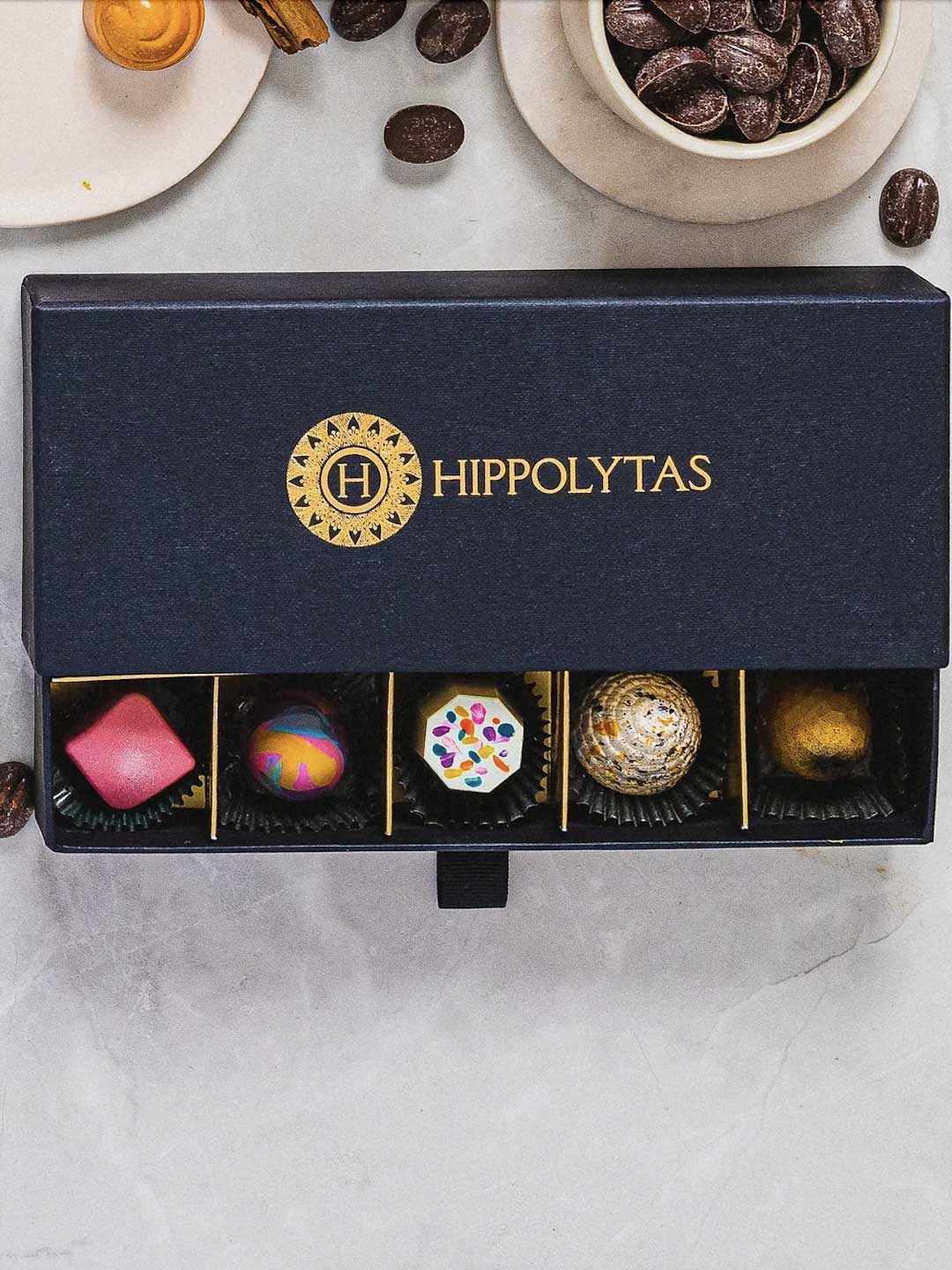

Packaging luxury chocolate is not just about aesthetics. It is a functional part of the process. Materials are chosen to protect against heat transfer, moisture, and physical damage while still presenting the product appropriately.

In a chocolate factory, packaging often happens in controlled stages. Chocolates are sealed once they have fully stabilised, reducing the risk of condensation or bloom. This is especially important when the chocolate is intended for hospitality or gifting, where presentation and consistency are critical.

Why Local Chocolate Production Matters in Hospitality

For hotels and hospitality groups, local production is not a nice-to-have. It is often essential.

Luxury chocolate used in turndown, minibar, or guest gifting programmes needs to be fresh. Most hotels do not want to store chocolate for long periods, especially when dealing with products that are sensitive to temperature and humidity.

Locally produced chocolate allows for shorter lead times and more frequent deliveries. This keeps stock fresh and reduces the risk of heat damage during transport. It also allows hotels to adjust quantities quickly during peak periods without compromising quality.

This is why many hospitality teams prefer working with locally made luxury chocolate rather than imported products that have spent weeks in transit and storage

Ongoing Supply and Consistency

Another advantage of working with a nearby chocolate factory is consistency. When production, packaging, and distribution are closely managed, it becomes easier to maintain the same standard across every delivery.

For hospitality, consistency matters as much as quality. Guests expect the same experience every time they visit. A reliable local supply supports this expectation while reducing operational complexity for hotel teams.

This is also why many hotels partner with chocolate factories in Cape Town that specialise in these types of chocolates rather than relying on generic suppliers.